Abstract

Structural and magnetic characterizations have been combined to investigate the growth kinetics of Ge1−xMnx diluted magnetic semiconductors (DMSs) on Ge(001) substrates by means of molecular beam epitaxy (MBE). We have identified the growth process window allowing stabilization of a high Curie temperature (TC) nanocolumn phase and provide evidence that the growth of semiconducting Ge1−xMnx nanocolumns and metallic Mn5Ge3 clusters is a competing process. Due to a continuous increase of the Mn concentration inside nanocolumns, induced by Mn segregation along the growth direction from the interface toward the film surface, nanocolumns become unstable when the Mn concentration reaches a value of ∼40 at.% then transform into Mn5Ge3 clusters. We propose a real-time approach to realize stacked layers consisting of nanocolumns separated by a Ge barrier layer, allowing exploitation of the effect of giant magneto-resistance in multilayer structures

Export citation and abstract BibTeX RIS

Content from this work may be used under the terms of the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

In recent years, the synthesis of Ge:Mn-based ferromagnetic materials has received growing interest, motivated by the hope that they would be promising candidates for the development of a new generation of spintronic devices [1–7]. To be compatible with the conventional Complementary Metal Oxide Semiconductor (CMOS) technology, ferromagnetic materials should not only have a high Curie temperature and a high spin polarization, but it should also be possible for them to be epitaxially grown on Si and/or Ge substrates. Ge 1−x Mn x diluted magnetic semiconductors (DMSs) would be potential candidates since they can easily be integrated into semiconductor heterostructures and spin injection from Ge 1−x Mn x DMS is expected to be highly efficient because of the natural impedance match to Ge. However, the use of Ge 1−x Mn x DMS has been greatly hampered by its low Curie temperature (T C ), which is well below room temperature [1, 2].

The origin of such a low T C in Ge 1−x Mn x alloys probably arises from a very low solubility of Mn in the Ge matrix, which favors the formation of embedded precipitates and/or clusters inside the alloys, thus conducting to the formation of highly heterogeneous materials. Different kinds of embedded Mn-rich phases have been identified, such as Mn-rich elongated structures [8], amorphous Mn-rich precipitates [9], self-assembled nanocolumns [10], and the most commonly observed is probably metallic Mn5Ge3 clusters [11, 12]. For spintronic applications, the nanocolumn phase appears particularly interesting since it remains ferromagnetic up to temperatures above 400 K and exhibits semiconducting conductivity [10]. The composition of nanocolumns has been attributed to Ge 2 Mn, a Ge-rich phase which does not exist in the bulk phase diagram [13]. In addition, it has also been shown that Ge 1−x Mn x nanocolumns are not a stable phase, they transform into metallic Mn5Ge3 clusters upon post-growth thermal annealing at a temperature of around 650 ° C.

In this work, we report on the growth kinetics of Ge 1−x Mn x nanocolumns on Ge(001) as a function of the Mn concentration, ranging from 1 to 14 at.%. We have chosen an intermediate growth temperature of 130–150 ° C to avoid a direct formation of metallic Mn 5 Ge 3 precipitates, which are generally formed at a growth temperature higher than 180 ° C [11, 12], or amorphous Mn-rich clusters stabilized at temperatures below 80 ° C [9]. We provide evidence on the growth instability of Ge 1−x Mn x nanocolumns, which are found to transform to Mn5Ge3 clusters when increasing the film thickness and the Mn concentration. In addition, by investigating Mn-doped Ge alloys with high Mn contents, we are able to obtain a Mn-saturated diluted matrix in between nanocolumns and Mn 5 Ge 3 clusters and can deduce the value of the highest T C , which can be obtained for a homogenous Ge 1−x Mn x alloy.

2. Experimental

Ge 1−x Mn x films were grown by molecular beam epitaxy (MBE) on epi-ready n-type Ge(001) wafers with a nominal resistivity of 10 Ωcm. The base pressure in the MBE system is better than 5×10−10 mbar. The growth chamber is equipped with a reflexion high-energy electron diffraction (RHEED) technique to control the cleanness of the substrate surface prior to growth and to monitor the epitaxial growth process. Ge 1−x Mn x films were obtained by co-deposition of Ge and Mn from standard Knudsen effusion cells, the Ge deposition rate was determined from RHEED intensity oscillations whereas the Mn deposition rate was measured by a quartz crystal microbalance. For Mn concentrations below 2%, the measurement uncertainty can reach a value of 10 at.%. The standard growth rate of Ge 1−x Mn x alloys used in this work is 1–2 nm min −1.

Structural analyses of the grown films were performed through extensive high-resolution transmission electron microscopy (TEM) by using a JEOL 3010 microscope operating at 300 kV with a spatial resolution of 1.7 Å. The magnetic properties were investigated using Quantum Design physical property measurement system (PPMS) and superconducting quantum interference device magnetometer (SQUID) with a magnetic field applied both in the plane of the sample surface and perpendicular to it. The diamagnetic contributions of Ge substrates were subtracted from the measurements, leaving the magnetic contributions of Ge 1−x Mn x films.

3. Results and discussion

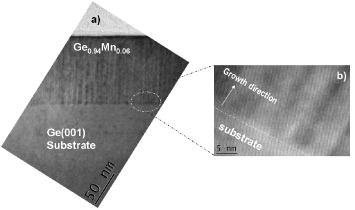

Due to a low solubility of Mn in Ge, the growth parameters, in particular the growth temperature, have been shown to greatly influence the growth kinetics of Ge 1−x Mn x alloys. In [10], it was reported that for growth temperatures below 100 ° C, nanocolumns are formed but exhibit a low Curie temperature, whereas for temperatures above 200 ° C Mn 5 Ge 3 crystallites appear. We have therefore chosen a growth temperature of 130 ° C and kept it constant in all experiments. Figure 1(a) displays a typical TEM image of an ∼80 nm thick sample with a Mn content of ∼6 at.%, i.e. the sample was grown at growth conditions similar to those reported in [10]. Dark contrast corresponds to Mn-rich regions. The image reveals the formation of nanocolumns with an average diameter of ∼5 nm and most of them lie along the growth direction.

Figure 1 (a) Typical cross-sectional TEM image of an 80 nm thick Ge 1−x Mn x film with x∼0.06. The image reveals the formation of nanocolumns with an average diameter of 5 nm. (b) High-resolution TEM image taken around the interface region, the nanocolumns are oriented along the growth direction and structurally coherent with the surrounding diluted matrix.

As can be seen from a high-resolution TEM image in figure 1(b), a number of nanocolumns starts growing from the interface and they coherently match the lattice of the surrounding matrix. This result is in agreement with that reported in figure 1(b) of [10]. Magnetic characterizations (not shown here) also reveal a similar behavior to that reported in figure 3(a) of [9], which displays a monotonous decrease of net magnetization with increasing temperature and confirms a Curie temperature well above 350 K, the upper limit of temperature measurements in our PPMS or SQUID. The comparison of the present data with those reported in [10] aims at indicating that we deal here with the unique high-T C self-assembled nanocolumns. Recently, we have investigated the nanocolumn composition by means of laser pulse atom probe tomography (LP-ATP) and found that nanocolumns did not have a defined and stoichiometric composition as currently believed [14]. The Mn concentration inside nanocolumns almost linearly increases from their base at the interface and can reach a value up to 40% in the region near the film surface. Ge 1−x Mn x nanocolumns can then be considered as a solid solution and not a Ge:Mn phase.

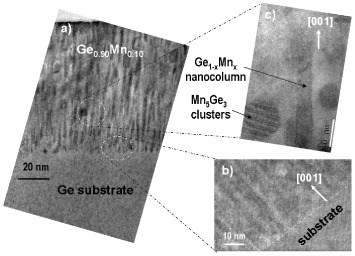

With a further increase of the Mn doping content in the alloys, TEM analyses reveal a particular mechanism along which the formation of nanocolumns and Mn5Ge3 precipitates is in competition. Figure 2(a) represents a typical TEM image of an ∼80 nm thick layer with an average Mn content of 10 at.%. Compared to the previous TEM image, one can observe here that nanocolumns have become somewhat disordered and their length has been shortened. As can be seen in figure 2(b) in the region near the interface, only nanocolumns are present, whereas at the film thickness of ∼30 nm going from the interface (figure 2(c)) Mn 5 Ge 3 clusters start to appear. Furthermore, the density and also the size of Mn 5 Ge 3 clusters are found to increase upon further increasing the film thickness. It is worth noting that nanocolumns mainly remain perpendicular to the layer interface while embedded Mn 5 Ge 3 clusters are randomly oriented. This result clearly indicates that nanocolumns become less and less stable with an increase of the Mn content when increasing the film thickness.

Figure 2 (a) Typical cross-sectional TEM image of a ∼80 nm thick Ge 1−x Mn x film with x∼0.10. Note that Mn 5 Ge 3 precipitates start to appear at a film thickness of ∼30 nm and from this thickness nanocolumns become less and less ordered when going up to the surface. (b and c) High-resolution TEM image taken in a region near the interface (b) and inside the layer (c).

How can we explain the formation of Mn 5 Ge 3 clusters after deposition of a certain thickness? To better understand the above phase transition, we recall that the Mn concentration inside nanocolumns is neither defined nor constant, it increases along the nanocolumn length, from the interface toward the film surface. Such an increase of the Mn concentration arises probably from a vertical Mn segregation toward the film surface. The highest Mn concentration measured in nanocolumns is about 40 at.%. This means that when the Mn concentration goes beyond this value, nanocolumns become instable and should transform to another phase, which has a higher Mn concentration.

In the Mn/Ge phase diagram [13], several phases have a Mn concentration equal to or higher than 60 at.%, such as Mn 5 Ge 3, Mn 5 Ge 2, Mn 3 Ge 2 and Mn 11 Ge 8. Among these phases, Mn 5 Ge 3 is the unique ferromagnetic phase which exhibits a Curie temperature at ∼296 K. In addition, it is now commonly accepted that embedded precipitates observed during growth of Ge 1−x Mn x DMS alloys are Mn 5 Ge 3 clusters [11, 12]. As can be seen below, the formation of Mn 5 Ge 3 clusters is also confirmed from magnetic characterizations. Note that Mn 11 Ge 8 is anti-ferromagnetic with a Néel temperature around 150 K, their formation can be ruled out from magnetic characterizations.

The above arguments appear to indicate that at a growth temperature of 130 °C, a too high Mn concentration inside nanocolumns could be the driving force of the nanocolumn instability and conduct to their transformation into Mn 5 Ge 3 clusters. To have a better insight into this, we have performed Ge 1−x Mn x growth with an average Mn content increasing up to 12–14 at.%. When the Mn content becomes high enough, it is expected that the formation of Mn 5 Ge 3 precipitates will be more favorable than nanocolumn because thermodynamically Mn 5 Ge 3 is a stoichiometric compound while a nanocolumn is only a solid solution.

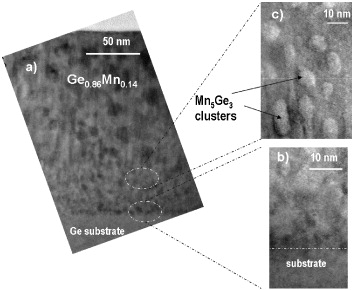

Figure 3(a) shows an overview TEM image of a sample corresponding to 14 at.% Mn. Clearly, almost no presence of nanocolumns is visible, the film now consists of clusters which are disordered and randomly distributed. From figure 3(c), one can observe some elongated structures but the film is mainly composed of precipitates separated by a diluted matrix. The three above TEM images also reveal that the size of precipitates increases when increasing the film thickness, a phenomenon that can be attributed to Mn segregation toward the film surface as in the case of the increase of the Mn concentration along nanocolumns.

Figure 3 (a) Overview TEM image of an ∼160 nm thick Ge 1−x Mn x film with x∼0.14 and high-resolution image around the interface region (b) and in a region inside the layer (c). Note that the layer is mainly composed of Mn 5 Ge 3 clusters, nanocolumns are completely absent in the layer.

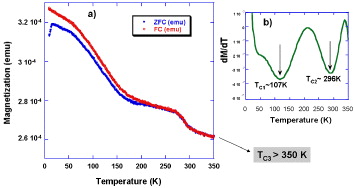

Figure 4(a) shows the temperature dependence of the magnetization measured by PPMS of the sample presented in figure 2 corresponding to 10 at.% Mn. First of all, the separation between the zero field cooled (ZFC) and field cooled (FC) curves confirms the presence of magnetic clusters inside the layer [10]. A magnetization value of 2.6×10−4 emu is still measured at 350 K, confirming the presence of a ferromagnetic phase with T C3 > 350 K. This phase can be unambiguously attributed to nanocolumns. A particularly interesting feature which can be observed in the figure is that the variation of magnetization versus temperature does not exhibit a monotonous decrease as being observed for samples containing only nanocolumns [10]. Figure 4(b) depicts the derivative of magnetization versus temperature, which reveals the presence of two other Curie temperatures: T C2, which is located at 296 K, can be unambiguously attributed to Mn 5 Ge 3 clusters whereas T C1, observed at 107 K, can be considered to stem from the diluted matrix. In addition, magnetic measurements of a sample with 14 at.% Mn (not shown here) indicates that magnetization is quenched at around 296–300 K, as expected for Mn 5 Ge 3 clusters. This is in good agreement with the above TEM analyses, indicating the absence of nanocolumns in the layer. The T C1, which arises from the diluted matrix in between precipitates, is found to slightly shift to a higher temperature of 115 K. Since Ge 0.90 Mn 0.10 and Ge 0.86 Mn 0.14 alloys are composed of three phases, diluted matrix, nanocolumns and/or Mn 5 Ge 3, it can be speculated that the diluted matrix is a homogenous phase in which the Mn concentration is saturated. In fact, any excess of Mn above its solubility limit in a Ge lattice has segregated to form Mn-rich phases, such as nanocolumns and/or Mn 5 Ge 3 clusters. In other words, a Curie temperature of about 115 K may be considered to be the highest value, arising from a homogenous Ge 1−x Mn x diluted matrix.

Figure 4 (a) Evolution of magnetization versus temperature of an ∼80 nm thick Ge 1−x Mn x film with x∼0.10. A separation between ZFC and FC curves suggests that magnetic clusters are present in the grown film. The Curie temperature (T C3) higher than 350 K can be unambiguously attributed to nanocolumns. (b) Derivative of magnetization versus temperature. The Curie temperature T C2 at 296 K is attributed to Mn 5 Ge 3 clusters while T C1 at 107 K arises from the homogenous dilute matrix in between nanocolumns and Mn 5 Ge 3 clusters.

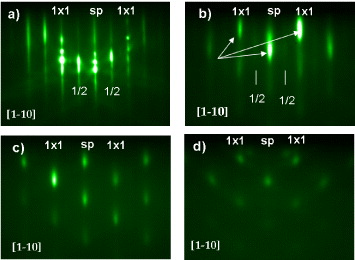

To exploit the unique magnetic and semiconducting properties of nanocolumns for device applications, a natural question arising is how to isolate nanocolumns from metallic Mn 5 Ge 3? As we have shown above, at a given Mn content, by means of TEM analyses one can determine the film thickness at which Mn5Ge3 clusters are formed. However, this kind of analyses requires a great number of TEM investigations, which should be carried out at numerous Mn contents. We propose here a real-time controlling approach to realize multilayer structures, which uniquely consist of nanocolumns and a Ge barrier layer separating those nanocolumns. In figure 5, we present a real-time evolution of RHEED patterns versus the film thickness, observed during Ge 1−x Mn x growth with a Mn content of 10 at.%. Starting from a well-developed two-dimensional RHEED pattern of the Ge surface prior to growth (figure 5(a)), nanocolumns grow up to a film thickness of ∼30 nm and the corresponding RHEED pattern is still characterized by a predominantly two-dimensional (2D) behavior, except for some reinforcement of intensity around bulk-like three-dimensional (3D) spots (indicated by white arrows in figure 5(b)).

Figure 5 RHEED pattern taken along [1–10] azimuth during the growth of an ∼80 nm thick Ge 1−x Mn x film with x∼0.10; The specular streaks (sp) together with (1×1) bulk-like streaks and half-ordered (1/2) streaks arising from the surface reconstruction are indicated; (a): pattern from the Ge surface prior to growth, (b) pattern observed during growth for film thickness below 30 nm, (c) for film thickness in the range between 30 and 50 nm and (d) for film thickness at ∼80 nm.

Note that a streaky pattern and half-ordered streaks are still observable at this growth stage. When Mn5Ge3 clusters are formed for film thicknesses above 30 nm, the film surface becomes so rough that the pattern is predominantly constituted of 3D spots (figure 5(c)). With a further increase of the film thickness, the density and also the size of Mn5Ge3 clusters increase, the growing surface becomes highly disordered and the pattern exhibits very faint 3D spotty patterns (figure 5(d)).

For a given Mn content, from RHEED analyses, we are thus able to detect in real time the beginning of Mn5Ge3 appearance. If we interrupt the film growth at the moment of 3D spot appearance, then grow on top a Ge barrier layer, it becomes possible to produce nanocolumn/Ge stacked layers without any metallic Mn5Ge3 cluster for the realization of giant magneto-resistance (GMR) multilayers. We have investigated the growth of such stacked layers with various Mn contents and thicknesses of the Ge barrier layer and studied their effect to the value of GMR. Work in this direction is in progress and will be published in a separate paper.

4. Conclusion

In conclusion, we have chosen an intermediate and appropriate substrate temperature of 130 °C to investigate the growth of Ge 1−x Mn x alloys as a function of the Mn concentration. We show that the formation of high-T C nanocolumns and Mn 5 Ge 3 clusters is a competing process and the process window for stabilizing the high-T C nanocolumn phase is relatively limited. The formation of nanocolumns is found to depend not only on the Mn concentration but also on film thickness. During growth, Mn continuously segregates toward the film surface and high-T C nanocolumns are found to transform to metallic Mn 5 Ge 3 precipitates when the Mn concentration inside nanocolumns exceeds a highest value of about 40 at.%. Not less important, we also show that the highest Curie temperature corresponding to a homogenousGe 1−x Mn x matrix is around 115 K. This implies that any attempt to obtain high-T C diluted materials for applications requires modifying the growth kinetics, for example by using carbon adsorption/doping [15] or surfactant-assisted growth, to suppress the Mn segregation. We also suggest a real-time approach to realize GMR multilayers containing only high-T C nanocolumns.